OUR STORY

In the year 2004, one of the leading medical Company’s in Durban had a major retrenchment, leaving numerous employees unemployed. A small group of them approached entrepreneur Mr. Rajen Reddy at that point in time to assist, create employment for a part of their crew. Due to the retrenchment and discontinuation of products, manufacturing machinery and equipment were stripped and ready to be scrapped, which was then purchased and became the starting point of the Champion Healthcare journey. The assembly of the machines took place at Hannah Road in Congella, Durban.

Due to the nature of the high quality products that were manufactured on these machines, specialized parts were not included in the purchase which created a restriction on the woven product range as the previous range of products were manufactured to SABS standards and specifications which made that company a leader in the field of manufacturing woven crepe bandages.

The key raw material for the bandage development was 100% cotton fibres which was sourced through local suppliers who relied on imports {China and India}. In a short space of time the Conti crepe bandage was developed and met hospital requirements and became the first successful product for the company. Further developments resulted in a better quality bandage which was the Versa crepe bandage and this product demand became greater.

The yarns were now sourced through a local supplier, Standerton Mills (www.standertonmills.co.za). The cotton plants are grown, hand-picked and processed to make up 100% natural cotton yarn threads in packages that were suitable for our warping and weaving processes (warp and weft). Whilst the crepe bandage production was in full production, other developments were in progress to meet the needs of hospital supplies.

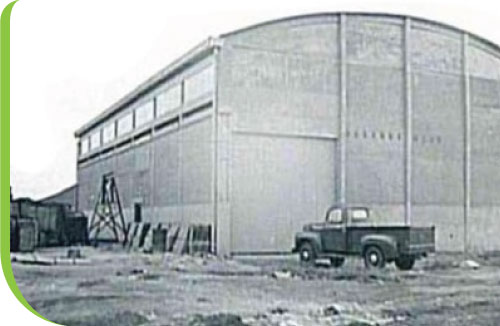

Standerton Mills raw material store 1947

Standerton Mills raw material

Standerton Mills bale

The maternity tampon was designed and developed (Fempon). The range then expanded to include 100% cotton cleansing swabs in three different sizes 30mm, 50mm and 65mm in two types, the plain swabs and X-ray detectable. Another development was the dissecting swabs which is also known as the 10mm X-ray detectable peanut swabs. Followed by the development of the Adult and Child skin traction kits. The work force grew close to a hundred employees. The range meets the SANS 945 standard. Competition was great due to imports from China and India and the struggle to supply on Government tenders to the Department of Health was almost impossible as a local manufacturer.

Over the years the need for sundries items became less, as imported products were in high demand again so the company had to downsize. With all the investments in training and developments many product lines were discontinued, as the decision makers to source products, did not consider supporting the local companies which were trying to reduce the unemployment rate in the country.

Continuous improvements were made to our core manufacturing processes and we then manufactured our new 100% cotton woven Vese crepe bandage which met the SANS 945 standard. We were awarded on the RT42 tender in 2018.

With guidance from the DTI we were also given the opportunity to have a stall at Africa Health 2018 and 2019.

Our future projects include the development of gauze which is used in various forms in the health sector which we want to partner with local gauze swabs manufacturers to produce 100% local gauze swabs.

Our aim is to set up mini CHC’s in all 9 provinces to ensure that the supply of our locally manufactured products are available to hospitals and clinics on time on request throughout South Africa.

We are in process of setting up as our training center will be at our main branch in Hannah Road. If you are interested in starting up a branch in any of the provinces, you can contact us via email or telephone.